There are two main ways to measure the water level in storage tanks. The first is to use a pressure sensor to measure the water pressure at the base of the tank. Often, the temptation is to simply put a tee on the suction side of the booster pump. That would be the simple fix; but anytime the booster pump is on, you will get bad data because the booster pump creates a suction that will lower the reading below the correct level.

The best practice for this is to install a new bulkhead into the tank so you have a dedicated measurement port. If your tank is in a place that might freeze, you should consider piping that line into your pump house so that your pressure transducer can be protected from freeze damage.

Of course, you’ll need to insulate that exposed pipe — if it freezes your reading will be off. Make sure you get your pressure transducer installed as low as possible but not below the bottom of the storage tank. When you choose a pressure transducer, make sure you select the proper range. While a 100-psi transducer will work, it’s best to choose one with the proper range so you get better accuracy for low-pressure applications. Typically, this would be a 0–100-inch version or a 0–15-PSI version.

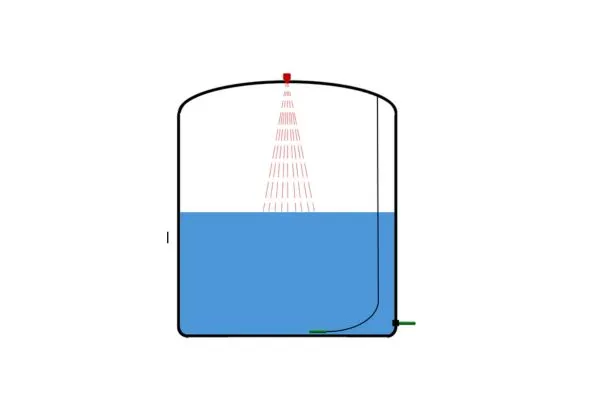

Another way you can measure the water level in the storage tank is with ultrasonic water level sensors. These are installed on top of the tank, and they bounce a sound wave off the top of the water to measure the water level. Usually, it’s best to install the sensor at least 24 inches away from any potential source of interference such as the edge of the tank, pipes, float switches, or splashing water. And it’s always a good idea to mount the sensor onto a horizontal surface that is level.

A third option is to use a submersible pressure sensor, just like the version you would install inside your well for measuring the static water level. But this version would probably be a 0–15 psi rated sensor. This option works great if you have a lot of splashing water that might interfere with an ultrasonic sensor — you wouldn’t have the freeze concerns that you would have with the standard pressure sensor. This option will likely be the most expensive option of the three, but it works great in all situations and will give you very clean data.

All three options have their place in the NightOwl Monitoring & Control System. Choose a sensor that will work best for your customer and your situation. We are glad to offer additional advice about these options. Just give us a call today to discuss.