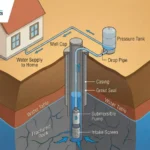

A well pump is one of the most essential components of a private well system. When it fails, water pressure drops, faucets slow down, and in many cases the entire household loses water. Whether you are a homeowner trying to understand the true cost of replacing a well pump or a drilling company looking for accurate pricing insights to guide your clients, this resource breaks everything down clearly.

This guide explains well pump replacement cost, professional installation fees, pump types, water well pump prices, and technical considerations that impact final pricing. It is built to be useful for homeowners researching costs and for drilling companies that want a reliable reference when estimating projects or answering customer questions.

NightOwl also plays a role in supporting well owners with smart monitoring that helps prevent early pump failure, over-cycling, and unexpected breakdowns. Whether you handle the installation yourself or hire a drilling company, monitoring protects the system long term.

Average Well Water Pump Replacement Cost

Most homeowners spend 700 to 2,800 for a complete well pump replacement. However, drilling companies know that costs can vary widely based on pump type, well structure, and installation complexity.

Below is a clear price overview that benefits.

| Pump Type | Average Installed Cost |

| Shallow well jet pump | 300 to 900 |

| Deep well jet pump | 500 to 1,500 |

| Submersible pump (standard) | 900 to 2,800 |

| High horsepower submersible (2 to 3 HP) | 2,000 to 4,000 |

| Well pressure tank replacement | 300 to 1,000 |

| Full well system upgrade | 3,500 to 15,000+ |

Costs vary because no two well systems are the same. The depth, water demand, pump horsepower, and electrical configuration all influence the final price.

Cost Factors That Affect Pump Replacement

Homeowners often ask why well pump replacement cost ranges so much. Drilling companies understand that several technical variables come into play during installation. Here is a breakdown that helps both groups.

1. Well Depth and Construction Type

The deeper the well, the more labor and equipment required to pull the pump and install a new one.

- Shallow wells (0 to 25 ft): easier and cheaper

- Deep wells (100 to 400 ft): require submersible pumps, lifting equipment, and more labor

Drilling companies must often calculate drop pipe length, torque arrestors, wire size, and pipe couplers, all of which affect pricing.

2. Pump Horsepower and Flow Rate

Horsepower directly impacts water well pump prices.

- Small homes: 0.5 to 1 HP

- Larger homes or irrigation systems: 1.5 to 3 HP

Higher horsepower pumps cost more and require heavier electrical loads.

3. Type of Pump Being Installed

Different pump systems have different costs:

- Jet pumps (shallow or deep): lower cost, above ground

- Submersible pumps: sit deep in the well, require more installation effort

- Constant pressure systems: advanced technology, premium pricing

Drilling companies often prefer submersible pumps for long term performance.

4. Labor and Technical Difficulty

Labor can be the biggest part of the well pump replacement price. Work becomes more complex when:

- Well depth is high

- Drop pipe is heavy steel

- Pump is stuck due to age or corrosion

- Wiring needs replacement

- Pump has failed in winter conditions

Drilling companies often charge 300 to 1,500 for labor depending on complexity.

5. Pressure Tank and Control Components

Many pump failures are caused by:

- A failing pressure tank

- A stuck pressure switch

- Faulty wiring or relays

If these components need replacement, the total cost increases by 100 to 1,000.

6. Water Quality and Sediment Conditions

Sediment, sand, iron, and minerals can damage pumps early.

Drilling companies often recommend:

- Sediment filters

- Iron removal systems

- Sand separators

These add 200 to 1,200 to the total cost depending on water quality.

Submersible Well Pump Replacement Cost

Submersible pumps are the most common choice for deep wells because they are efficient, long lasting, and quieter than jet pumps.

Typical Costs

- Pump price alone: 300 to 1,200

- Installation labor: 500 to 1,500

- Total installed: 900 to 2,800

- High horsepower (2 to 3 HP): 2,000 to 4,000

Drilling companies rely on special retrieval tools, safety equipment, torque arrestors, and proper wire gauge calculations during installation.

Shallow and Deep Jet Pump Replacement Cost

Shallow Well Jet Pumps

- Pump cost: 150 to 500

- Installation: 150 to 400

- Total: 300 to 900

Deep Well Jet Pumps

- Pump cost: 300 to 700

- Installation: 250 to 800

- Total: 500 to 1,500

These pumps sit above ground and require priming. Drilling contractors know that they are easier to replace but less efficient than submersible pumps for deeper wells.

Well Pump Repair Cost

Not every pump failure requires full replacement. Repairs can be cost effective, especially for newer systems.

Common Repair Costs

| Repair Type | Cost |

| Pressure switch replacement | 80 to 200 |

| Foot valve replacement | 150 to 400 |

| Wiring repairs | 100 to 350 |

| Minor pump repair | 150 to 600 |

| Well pressure tank repair or replacement | 300 to 1,000 |

Drilling companies usually diagnose repairs before recommending replacement.

Technical Factors Drilling Companies Consider

1. Static Water Level and Drawdown

Pump sizing depends on:

- Static water level

- Pumping water level

- Drawdown rate

Contractors calculate these values to prevent pump burnout.

2. Drop Pipe Material

Costs vary depending on:

- Poly pipe

- Galvanized steel

- PVC

- Torque arrestors

- Safety rope

- Stainless steel clamps

Steel drop pipe increases labor time and replacement cost.

3. Electrical Load and Control Box Compatibility

Higher horsepower pumps require:

- Larger gauge wire

- Two wire vs three wire control boxes

- Capacitor checks

- Proper grounding

These technical factors increase installation time and cost.

4. Well Casing Condition

Older wells may have:

- Rust buildup

- Narrow casings

- Blocked pump sleeves

These issues increase labor cost for drilling companies and installation teams.

Signs You Need a New Well Pump

For homeowners:

- No water or very low pressure

- Pump constantly running

- Dirty or cloudy water

- Sputtering faucets

- High electricity bills

- System short cycling

For drilling companies:

- Pump overheating

- Broken impellers

- Burned control box

- Worn drop pipe couplers

- Wiring insulation failure

If multiple issues appear, full replacement is more cost effective.

Cost to Replace a Well Pump and Pressure Tank

Pressure tanks often fail before pumps. If both need replacement:

- Pump: 900 to 2,800

- Tank: 300 to 1,000

- Together: 1,500 to 3,500

Drilling contractors often upgrade tanks to extend pump lifespan.

DIY vs Professional Installation

Homeowners may consider DIY, but drilling companies know the risks.

DIY Costs

- Pump: 150 to 1,200

- Tools: 50 to 300

- Risk of dropping the pump: very high

- No warranty on installation

Professional Installation

- Safe removal and installation

- Correct pump sizing

- Electrical compliance

- Warranty protection

Most drilling professionals strongly recommend against DIY for deep wells.

How Long Do Well Pumps Last?

Average lifespan: 10 to 15 years

Factors that shorten lifespan:

- Sediment

- High iron

- Continuous cycling

- Undersized pressure tank

- Electrical issues

NightOwl Monitoring helps extend pump life by tracking water usage and identifying early failure signs before they turn into major repairs.

Final Thoughts

The cost of replacing a well pump depends on pump type, depth, horsepower, labor difficulty, and the condition of the overall system. Homeowners get clarity on pricing and expectations, while drilling companies benefit from a structured, technical overview that reflects real installation conditions.

Whether you manage your well system yourself or work with a professional drilling company, investing in quality equipment and smart monitoring ensures reliable water flow and fewer long term issues. NightOwl provides added protection through real time alerts, usage tracking, and early failure detection, helping both homeowners and drilling contractors reduce risk and avoid expensive emergency repairs.